ISSS608 2016-17 T3 Assign QIAN HONGJUN

Contents

Background

Introduction

With the passage of the Mistford Pact of 2010, the town and the Preserve have set into place certain safeguards to help ensure the safety of the people, animals, and vegetation of our area. When Mistford began growing its manufacturing industry, both the town and the companies wished to ensure an environmentally sound and economically supportive partnership. With these aims in mind, air sampling sensors have been placed near the town and in the Preserve to monitor air quality.

However, after placing monitors aroung the companies, they find the release of the chemicals of these factories are not optimistic. They need to find out more about the release chemicals and these companies to better protect the environment.

To better understand the problem, here are some introductions about the chemicals and factories.

Chemicals:

Appluimonia – An airborne odor is caused by a substance in the air that you can smell. Odors, or smells, can be either pleasant or unpleasant. In general, most substances that cause odors in the outdoor air are not at levels that can cause serious injury, long-term health effects, or death to humans or animals. However, odors may affect your quality of life and sense of well-being. Several odor-producing substances, including Appluimonia, are monitored under this program.

Chlorodinine – Corrosives are materials that can attack and chemically destroy exposed body tissues. Corrosives can also damage or even destroy metal. They begin to cause damage as soon as they touch the skin, eyes, respiratory tract, digestive tract, or the metal. They might be hazardous in other ways too, depending on the particular corrosive material. An example is the chemical Chlorodinine. It has been used as a disinfectant and sterilizing agent as well as other uses. It is harmful if inhaled or swallowed.

Methylosmolene – This is a trade name for a family of volatile organic solvents. After the publication of several studies documenting the toxic side effects of Methylosmolene in vertebrates, the chemical was strictly regulated in the manufacturing sector. Liquid forms of Methylosmolene are required by law to be chemically neutralized before disposal.

AGOC-3A – New environmental regulations, and consumer demand, have led to the development of low-VOC and zero-VOC solvents. Most manufacturers now use one or more low-VOC substances and Mistford’s plants have wholeheartedly signed on. These new solvents, including AGOC-3A, are less harmful to human and environmental health.

Factories:

Roadrunner Fitness Electronics – Roadrunner produces personal fitness trackers, heart rate monitors, headlamps, GPS watches, and other sport-related consumer electronics.

Kasios Office Furniture – Kasios Office Furniture manufactures metal and composite-wood office furniture including desks, tables, and chairs.

Radiance ColourTek – Radiance produces solvent based optically variable metallic flake paints.

Indigo Sol Boards – Indigo Sol produces skateboards and snowboards.

Data Description

Location coordinates

The factories and sensors locations are provided in terms of x,y coordinates on a 200x200 grid, with (0,0) at the lower left hand corner (southwest). The sensors map shows the locations of the sensors and factories by number for the sensors and by name for the factories.

Factory coordinates

Roadrunner Fitness Electronics: 89,27

Kasios Office Furniture: 90,21

Radiance ColourTek: 109,26

Indigo Sol Boards: 120,22

Sensor coordinates

1: 62,21

2: 66,35

3: 76,41

4: 88,45

5: 103,43

6: 102,22

7: 89,3

8: 74,7

9: 119,42

Raw data

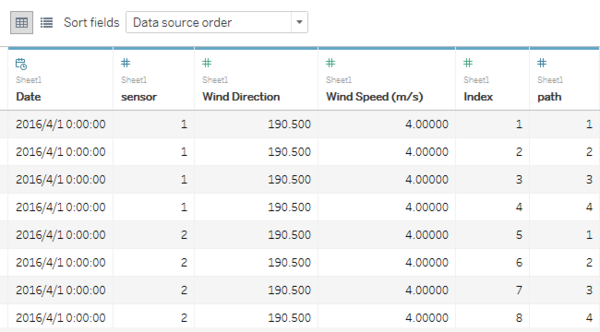

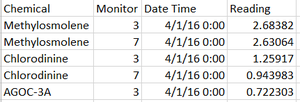

There are mainly two spreadsheet for the visualization object. The first one is the main data called "Sensor Data". It describes the readinds of chemicals detected by monitors in different time. The other data is Meteorological data showing the wind speed and wind direction in the three months. The folloings are the examples of these two data and the explanation of each column in the data.

Sensor Data

Chemical: Which one of the four chemicals detected by the sensors

Monitor: Which one of the nine sensors picking up the reading

Reading: The air sensor detected amount in parts per million

Date Time: The date and time of day of the reading, local time with no change for Daylight Savings.

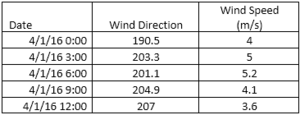

Meteorological data

Date: The date and time of the readings, local time with no change for Daylight Savings.

Wind Direction: The compass directions where the wind is originating from, using a north-referenced azimuth bearing where 360/000 is true north.

Wind Speed: The speed of the wind in meters per second.

Each of these reading is taken at the date and time provided.

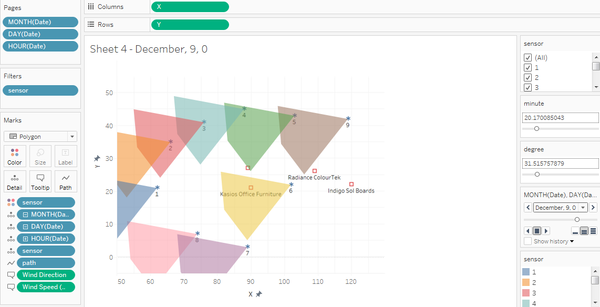

Data and visualization preparation

To make the visualization of the wind, there are some preparation steps need to be done.Specifically, to evaluate the effect of chemecal release and the responsable factories, an area from sensor need to be displayed to see which factory is in the area at the time. If the release if high, then we can directly find out which factories should be reponsible. To draw an area or a fan shape, each sensor needs three other points based on the wind direction and wind speed arount itself.Then these points together with the sensor can make a polygon or fan shape.

Step1:Insert new columns

Insert two columns named index and path separetly. For each sharp hour, it needs 36 points to make 9 polygens becasue there are total 36 sensors. So for each time, the index should be from 1-36. Then the path helps each sensor to form a seperate area.

Step2: Join the two tables based on the same column which is "Date"

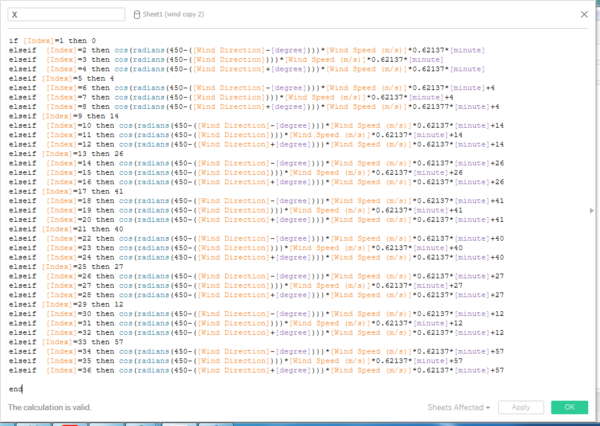

Step3: Calculate X

If the index=1,5,9,13........, then the location if the sensor itself. Then based on the wind direction and wind speed, we can used the formula to calculate the corresponding location. Specifically, degree, wind speed and minute are configured as parameters in order to change the shape of the area. The number 0.62137 is transferred from 1m/s to 1 mile/s and fit it into a 200*200 grid.

Step4: Calculate Y

Then we can use the same method to calculate Y coordinate.

Step5: Draw the graph

Drag X and Y to Columns and Rows respectively. Drag Sensor to Details and Path to Path and change the type to "Polygon". These are the most important steps to make graph. The other parameters need to be dragged into corresponding field to have the same graph shown above

Answer to the tasks

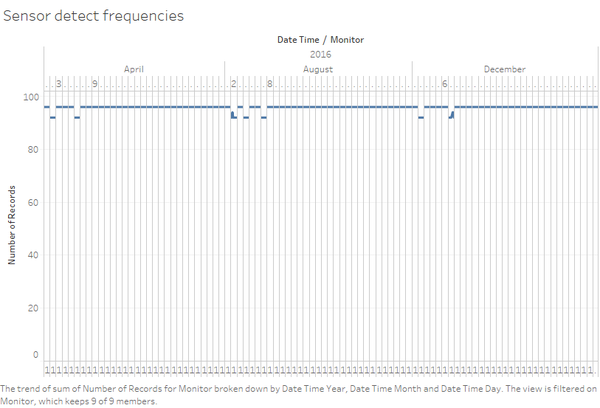

Task1. Detect sensor performanc

Sensor detection frequencies

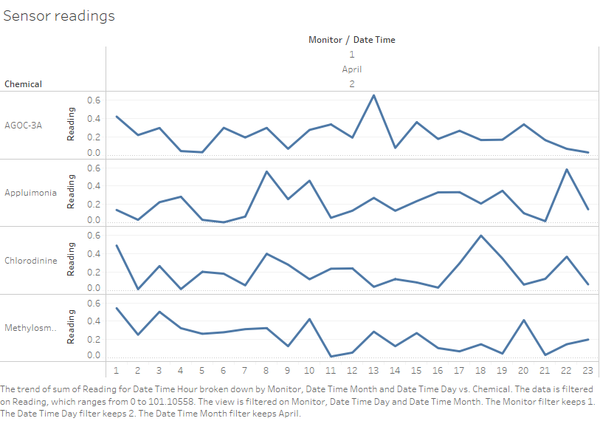

Normally, each monitor will have readings for each of four chemicals every one hour from 0:00 to 23:00. That means each monitor will detect 4*24=96 times each day. However, from the graph above, we can see in some days, the monitor only detects 92 times or 94 times each day. Namely, these days are April 2, April 6, August 2, August 4, August 7, December 2 and December7. These abnormal detection frequencies are questionable and require further investigation.

Take the monitor1 in April 2 as an example, we can find the it starts detection from 1:00 am but normally the monitor starts detection from 0:00. The rest of abnormal detections are the same situation which the sensors start detection from 1:00 instead of 0:00. The reason may be the sensors are not working properly in these years. However, this one hour gap may give the factory some opportunities to discharge the chemicals illegally. Furthermore, we can see a downward trend from 1:00 to 2:00, which means it’s highly possible the factory may discharge more chemicals from 0:00 to 1:00 but the sensor was not working properly at that time period.

Some questionable gaps

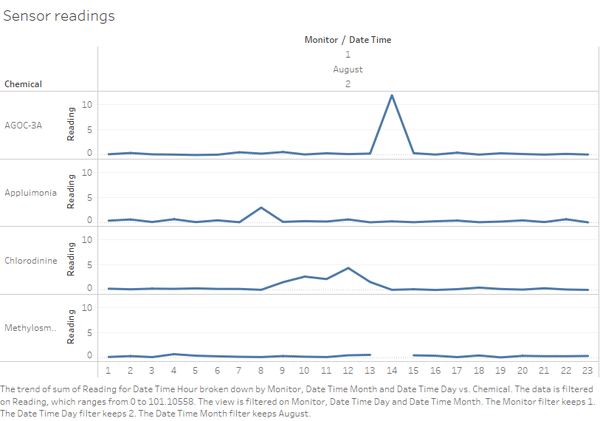

The graph above is an example of these gaps showing the readings of monitor1 in August 2. We can see from the graph, there’s a gap between 13:00 and 15:00. It means there’s no reading of the chemical Methylosm at that 14:00. Actually, these gaps very common in other monitors and in other dates. We may infer that these gaps are caused because the monitors are not working properly. However, each time when there’s no reading for Methlosm, the readings of AGOC-3A always increase dramatically.

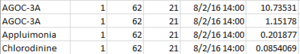

Then when we trace back to that period, we can find that actually the recordings are wrong because there are no records of Methlosm at 14:00 August 2 but AGOC-3A was recorded twice. That’s the reason why we see so many gaps. The recording system must be upgraded or fixed to record the readings of corresponding chemicals properly.

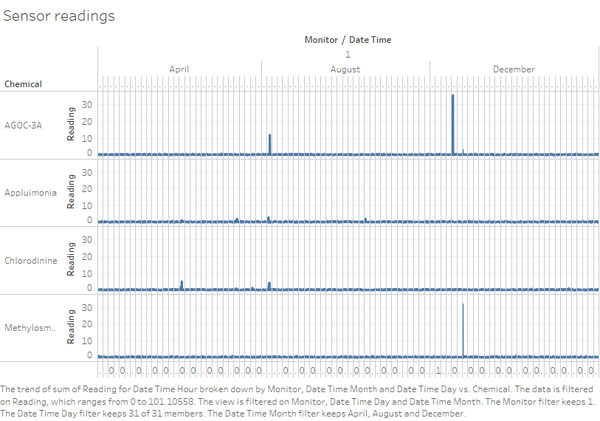

Some extreme high readings

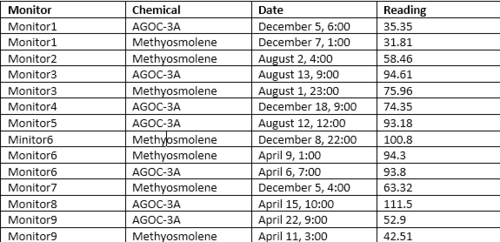

As can be seen in the graph above which is the readings of monitor1 in the 3 months, some readings are extreme high in the range of its corresponding monitors. The following table summarizes some extreme high readings for different monitors. These high readings are also questionable because they are quite outstanding from the normal range. The reason may be the sensors were not working properly or there were some external environmental factors such as wind. The reasons will be further investiged in the later parts.

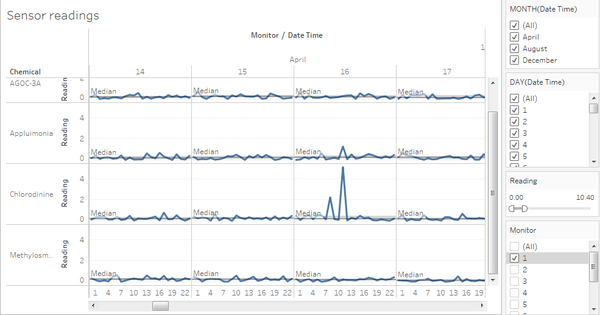

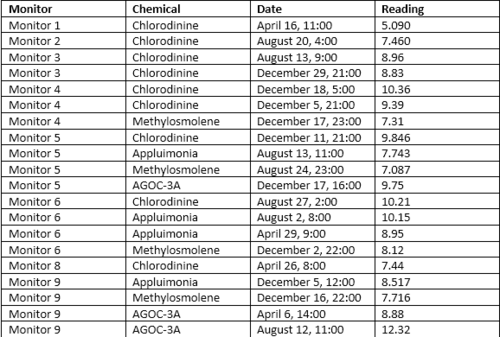

Some other high readings

Except for some extreme high readings, there are also some other high readings in the fluctuation range. For example, the graph above shows the readings of monitor 1 in the middle of April. We can see that for each chemical there’s a reference line showing the median with quartiles and the median value of Chlorodinine is 0.199 but the value in April 16 11:00 is at 5.090. This is a high value compared to the median value and needs further investigation. Especially, we will put more focus on the reading of chemical Chlorodinine because Corrosives are materials that can attack and chemically destroy exposed body tissues. It is a dangerous chemical to our environment and human beings.

Some other high readings are shown in the following table.

Note:

- Monitor 3 has the largest fluctuations in the reading

- Most high value in the chemical AGOC-3A is due to the wrong recording.

Task2. Chemical exploration

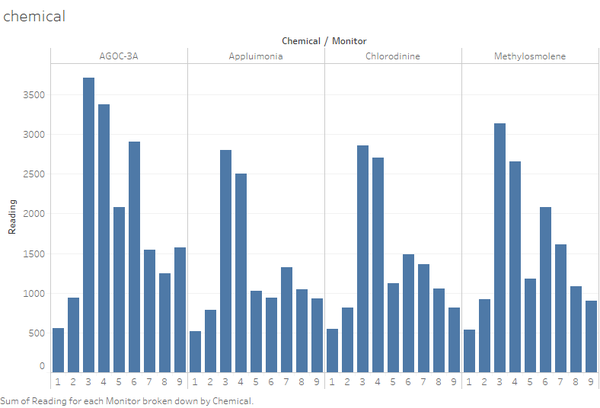

Relationship between sensor and chemicals

The graph above shows under each chemical group, which monitors detected the most reading. Monitor 3 and monitor 4 always have the highest reading among the four chemicals. For AGOC-3A, monitor 6 and monitor 5 also detected very high reading after monitor 3 and 4. For Appluimonia, monitor 7 and monitor 8 ranks 3rd and 4th of the reading. For Chlorodinine and Methylosmolene, monitor 6 and monitor 7 has the 3rd and 4th highest reading.

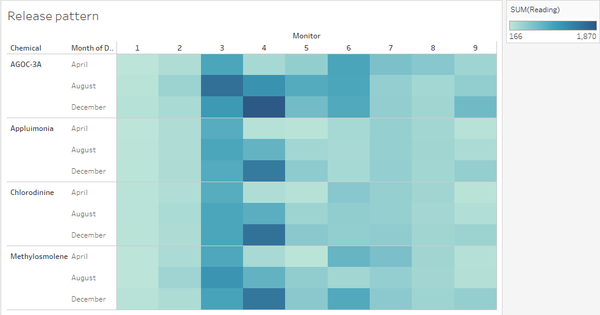

Release patterns

The graph above shows the chemical release pattern in different months. It is very clear that for monitor4, the release for all the four chemicals increase from April to December. Monitor 3 always detect high release in the three months but the release of AGOC-3A in August is higher than other months. Monitor5 and monitor6 detects higher release for AGOC-3A.

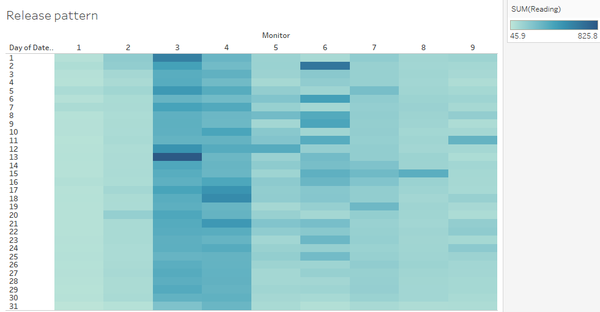

In terms of which day in a month has higher release, monitor 3 and monitor 4 detect higher release everyday compared to other monitors. Monitor 3 has extreme high release in the first day and 13th day in a month. Monitor 4 detect some high release during the middle of the month. Monitor 6 has high release at the 2nd day and the rest of release seem to have a high release intervally.

Then if we break down to hours, we find the chemicals release most at 6 o’clock and 4 o’clock in the morning. 13:00 and 9:00 also have relatively high release.

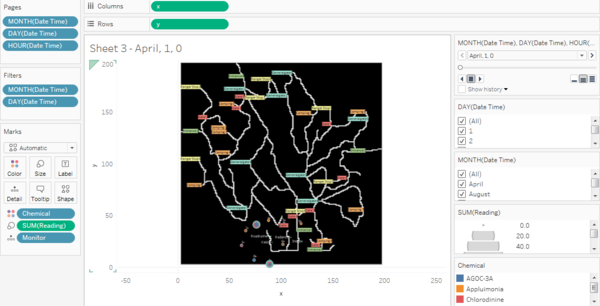

Interactive hourly release pattern

https://public.tableau.com/profile/hjqain#!/vizhome/trial_50/Sheet3?publish=yes

This tool helps to detect more detaily the realease of every hour in different days and different months. The position of the circle is the position of the 9 monitors. The size of the circle represents the release reading and the larger the circle is, the larger is the reading. The color represents differet chemicals. The color of the external circle means the chemical that releases the most at time.

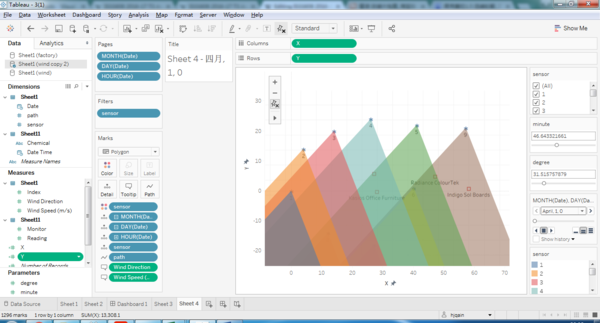

Task3. Define which factories are responsible for which chemical release

Wind visualization tool

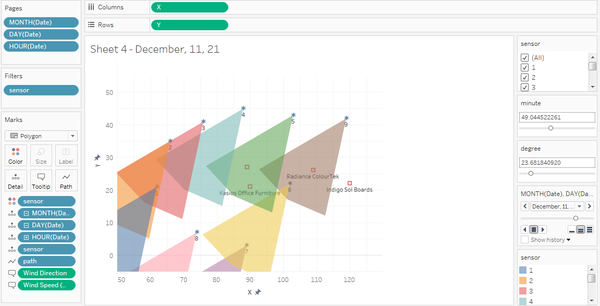

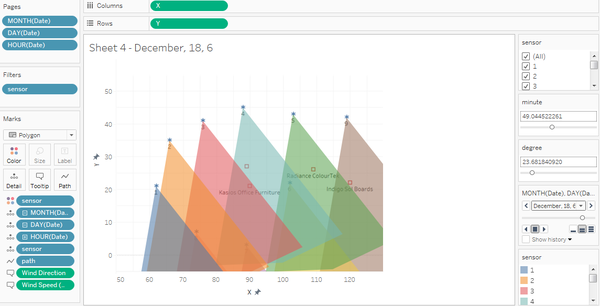

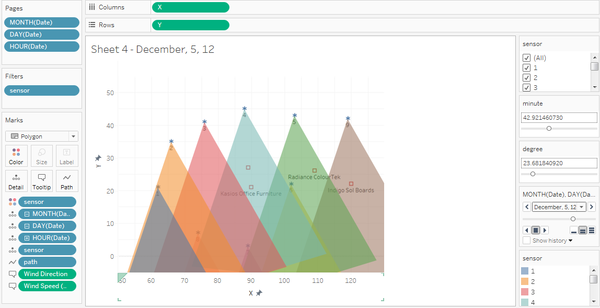

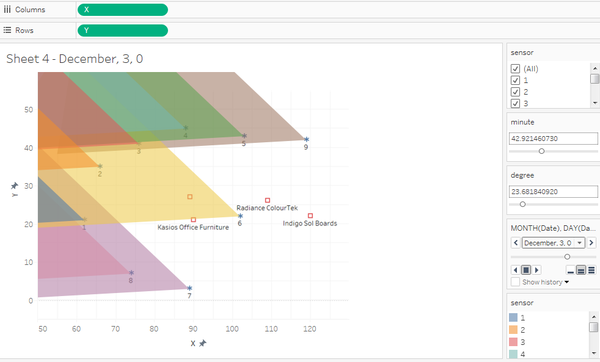

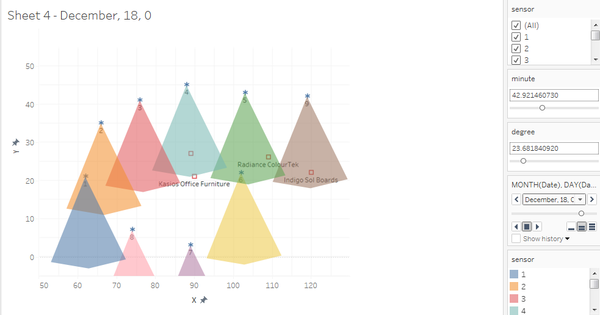

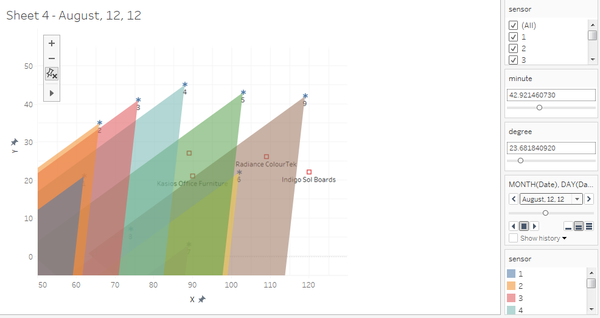

The application made to visualize the wind direction is shown as above. The blue point represents 9 different sensors and the red circle in the middle means different factories. The symmetry axis of the polygon represents the wind direction and the polygon area represents the cover area of the wind in a certain period. If the factory falls in the area, it means this factory should be responsible for the reading of that monitor. The color helps define the resource of the chemical release more clearly.

The first implication from this graph is that because monitor3 and monitor4 have the highest readings and they are quite near Roadrunner and Kasios, it can be inferred that these two factories probably produce more chemical release

Examine extreme high readings

This is the table defined in the first part of the extreme high readings. Here we are going to use the visualization application to see if there’s a relationship between the wind and the readings and which factories should be responsible. From a preliminary examination, all the high readings about AGOC-3A is due to the wrong records so we will focus on the chemical Methyosmolene.

In the table, we can see monitor 6 detects high release of Methyosmolene in December 8, 22 and when we trace back to the wind visualization, it shows Kasios Office Furniture is in the area of the monitor. The same findings are also shown in other time periods. It means the release of these high Methyosmolene is highly possible from Kasios Office Furniture and it’s not because the sensor is working improperly.

Factory detection

1.Chlorodinine

Chlorodinine has high reading on December 11, 21:00 on monitor 5 and we can see both Roadrunner and Kosias fall in the area.

This graph shows the area on December 18, 5:00 of monitor 4 and three factories are in the area. It can be inferred that the high reading of Chlorodinine may result from the release of multiple factories such as Roadrunner, Kosias and Radiance.

2. Appluimonia

Appluimonia has high reading on April 29, 9:00 on monitor 6 and this graph represents area in corresponding period. Radiance falls in the area so it may responsible for the release.

Appluimonia also has high reading on December 5, 12:00 on monitor 9. In this case, Indigo falls into the area.

3. Methylosmolene

Methylosmolene has high reading on December 2, 22:00 on monitor 6 and it can be seen Roadrunner can be the source.

Methylosmolene also has high reading on December 17, 23:00 on monitor4 and it proves that Roadrunner should be responsible for the release of Methylosmolene.

4. AGOC-3A

Apart from extreme high release of AGOC-3A from Kasios, Radiance may be another source for the release of this chemical. This graph shows the area on August 12, 11:00 of monitor 9.

To conclude, Roadrunner, Kosias and Radiance together may be responsible for the release of Chlorodinine. Radiance and Indigo are possible to be the source of Appluimonia. It is highly possible that Roadrunner produce high Methylosmolene release. Last but not least, Kasios and Radiance can be source of chemical AGOC-3C.

Feedback

Feedback from Xintian

Hi Hongjun,

I've read the solutions and here are my advises:

1) In terms of release pattern, it is much better to make an hourly reading heat-map. In this way, you can easily find the missing values.

2) In terms of wind visualization, I think it is no need to set different color into different sensors. And if you can put the center of fan-shapes on the factory, it will be much more visualized.

Regards,

Xintian

Feedback from Jiaqi

Hi Hongjun,

The 'interactive hourly release pattern' chart is interesting. It might look better if you put it on a lighter color background.

Thanks, Jiaqi