ISSS608 2016-17 T3 Assign KRUTIKA BALVEER CHOUDHARY

Contents

Overview

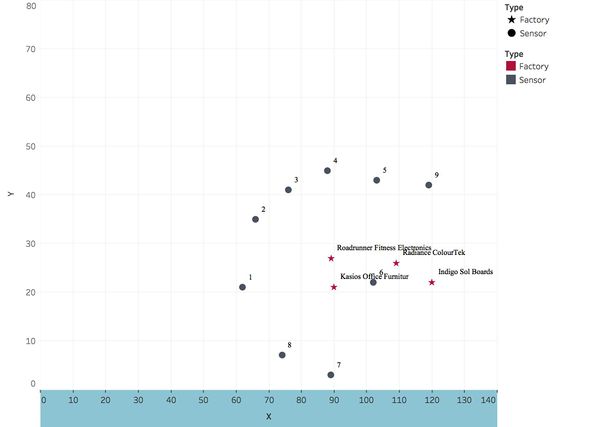

VAST provides information of sensor, wind, factory and chemical. There are nine sensors and four factories in the Lekagul Wildlife Preserve Area. Their locations are as following:

Chemical Description

Appluimonia

An airborne odor is caused by a substance in the air that you can smell. Odors, or smells, can be either pleasant or unpleasant. In general, most substances that cause odors in the outdoor air are not at levels that can cause serious injury, long-term health effects, or death to humans or animals. However, odors may affect your quality of life and sense of well-being. Several odor-producing substances, including Appluimonia, are monitored under this program.

Chlorodinine

Corrosives are materials that can attack and chemically destroy exposed body tissues. Corrosives can also damage or even destroy metal. They begin to cause damage as soon as they touch the skin, eyes, respiratory tract, digestive tract, or the metal. They might be hazardous in other ways too, depending on the particular corrosive material. An example is the chemical Chlorodinine. It has been used as a disinfectant and sterilizing agent as well as other uses. It is harmful if inhaled or swallowed.

Methylosmolene

This is a trade name for a family of volatile organic solvents. After the publication of several studies documenting the toxic side effects of Methylosmolene in vertebrates, the chemical was strictly regulated in the manufacturing sector. Liquid forms of Methylosmolene are required by law to be chemically neutralized before disposal.

AGOC-3A

New environmental regulations, and consumer demand, have led to the development of low-VOC and zero-VOC solvents. Most manufacturers now use one or more low-VOC substances and Mistford’s plants have wholeheartedly signed on. These new solvents, including AGOC-3A, are less harmful to human and environmental health.

Factory Description

Roadrunner Fitness Electronics

Roadrunner produces personal fitness trackers, heart rate monitors, headlamps, GPS watches, and other sport-related consumer electronics. Roadrunner began as one of the region’s first fitness stores in 1962, with an eye toward outfitting the entire nation with appropriate outdoor gear. After an earthquake nearly destroyed their main warehouse in 1968, Roadrunner turned a bad situation into a glowing success with the first “slightly damaged goods” sale. After which they began to focus on manufacturing; though their “Earthshaking Bargains” business still sells dented, overstocked and refurbished items over the internet and from a small retail shop attached to their front office.

Kasios Office Furniture

Kasios Office Furniture manufactures metal and composite-wood office furniture including desks, tables, and chairs. Kasios wants to do with desk chairs what Starbucks did for coffee – making office furniture what people must have, instead of what they just need. “Office equipment doesn’t need to be ugly!” says founder Ken Kasios. “We have redesigned all office products to be cool, fun, and hip—even your basic stapler.” Kasios business model is focused on in-store merchandising highlighting the beauty and functionality of their “user-centered design”. They recently celebrated the one-year anniversary of a distribution and merchandising agreement with the national office supply chain store PaperKlips.

Radiance ColourTek

Radiance produces solvent based optically variable metallic flake paints. “Metallic paints with an untarnished reputation!” quips ColourTek’s Senior Vice President Arthur Donner. “Radiance ColourTek metallic paints are worth their weight in gold.” Offering a new generation of paints in the 1970s, Radiance out marketed all competitors for three decades until manufacturing process issues began to tarnish their reputation. “We were challenged,” said Donner. “Polishing up our pearlescent pigments caused us to lose luster, but now we have the lowest VOCs (volatile organic compounds) in the industry!”

Indigo Sol Boards

Indigo Sol produces skateboards and snowboards. Founder Billy Keys started off manufacturing wooden wine barrels for northwestern US wineries, but then navigated a course from decorative fiberglass wine barrels to making his first pair of fiberglass skis in 1971. Excellent product and sales decisions rocketed Keys Skis production to unexpected levels, until they were bought out by a large Denver, Colorado-based private investment group. Keys returned to making specialized snowboards in the 1980s, with a small company in Mistford called Indigo Sol. The company has seen modest growth in recent years.

Data Description

The Meteorological data represents 3 months of readings in the following format: Date: The date and time of the readings, local time with no change for Daylight Savings. Wind Direction: The compass directions where the wind is originating from, using a north-referenced azimuth bearing where 360/000 is true north. Wind Speed: The speed of the wind in meters per second.

The Sensor data (provided in an Excel spreadsheet) contains 3 months of readings in the following format: Chemical: Which one of the four chemicals detected by the sensors Monitor: Which one of the nine sensors picking up the reading Reading: The air sensor detected amount in parts per million Date Time: The date and time of day of the reading, local time with no change for Daylight Savings.

Data Preparation

For all the analysis, Both the meteorological and sensor data has been combined using left outer join on the Date Time variable.

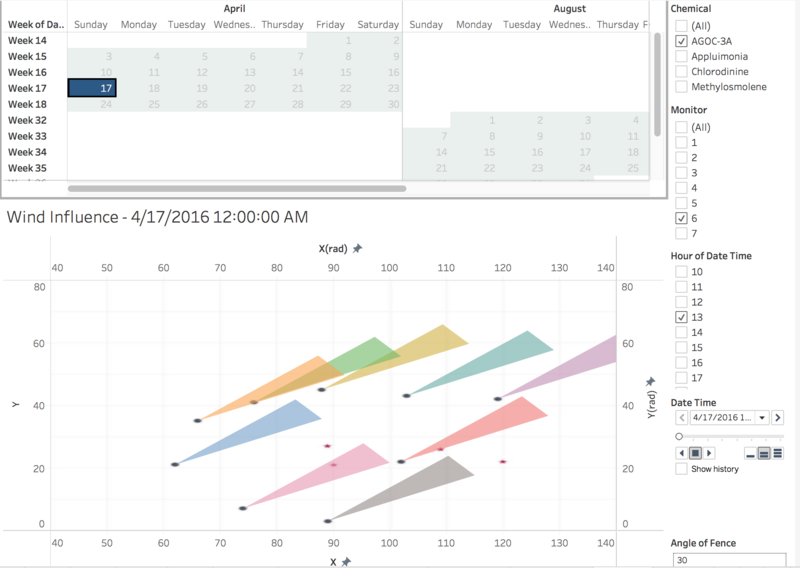

Air Plume Model For Analysis of Factories:

1.For the Air Plume Model, Sensor and Meteorological Data were combined using an Inner Join on the Date Time variable. After combining this data, 3 copies of each entry were created to generate 3 X,Y coordinates for every observation to plot a triangle on the plot. For each copy a Path Id was created which ranged from 1 to 3 .

2. After combining the data, a new parameter called Angle of Fence was created to make the angle user defined. By default it was set on 30.

3. Wind Speed was converted to miles per hour and then converted to grids to be able to scale the plot according to the measurements of the park given.

Formula: [Wind Speed(mph)]*(200/12)

4. Angle variable was created with the formula that generated 3 angles in equal gaps as denoted by the Angle of Fence Parameter. For ex: For wind direction 190, the angles generated were 175,190,205 with angle of fence as 30.

Formula:IF [Path Id]=1 then [Wind Direction]-([Angle of Fence]/2)

ELSEIF [Path Id]=2 then [Wind Direction]

ELSE [Wind Direction]+([Angle of Fence]/2)

END

5. Using the angle variable, X was calculated by adding the wind speed in grids to the sin of the angle and the origin X coordinate which is the x coordinate for the sensor.

Formula: IF [Path Id]=1 then [X]

ELSE

[X]+([Wind Speed( Grids)]*SIN(RADIANS([angle])))

END

6. Similarly for Y the following formula was used:

Formula:IF [Path Id]=1 then [Y]

ELSE

[Y]+([Wind Speed( Grids)]*COS(RADIANS([angle])))

END

7. For the final plot, all the sensors and the factories were plotted using the X,Y coordinates provided in the challenge. After plotting, the graph was saved as a png image and loaded on as a background image in the plot where the plume's for each sensor were plotted. This was done to understand what factories fall under the area of influence for a particular sensor reading at that time.

Tableau Workbook Link

Analysis of Sensors

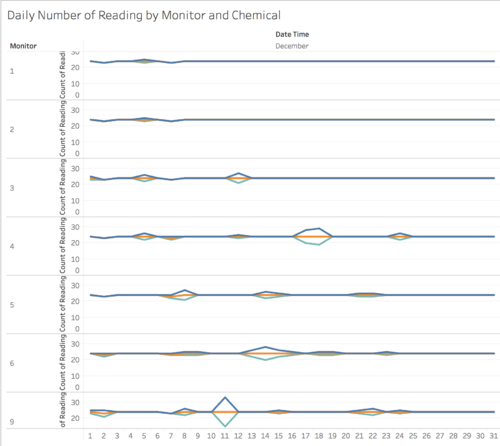

Non-Functional Sensors

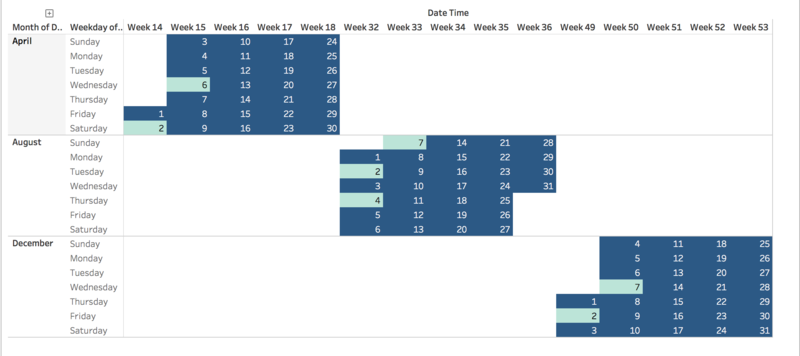

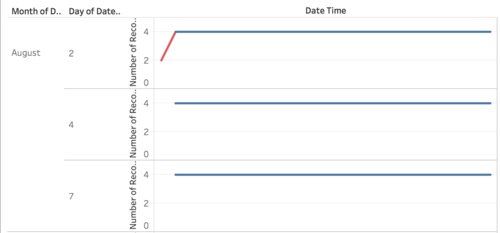

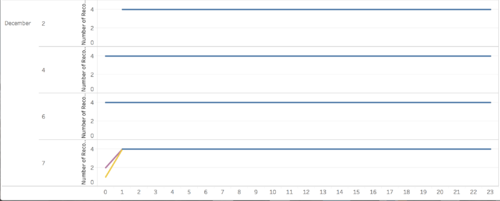

As seen in the figure, 2nd and 6th of April, 2nd,4th,7th of August and 2nd and 7th of December are the days when the sensors are recording less readings than the usual number of recordings. When these days were further investigated, the following was seen:

April: 2nd, 4th at 12:00 am none of the sensors recorded any readings.

August: on 2nd August only monitor 3 recorded any readings for 12:00 am while for both 4th and 7th none of the sensors worked at 12:00 am.

December: On 2nd December at 12:00 am none of the sensors recorded any readings whereas on 7th December only monitor 6 and 7 recorded some readings at 12:00 am.

Sensors with Erroneous Function

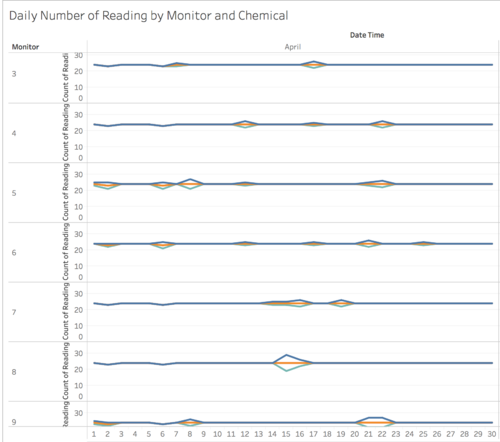

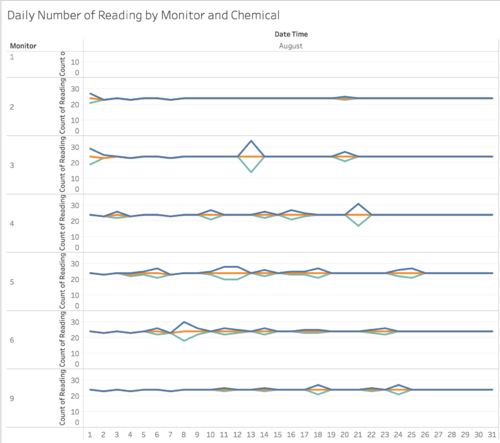

Here, the sensors have been analysed to see if at any given point in time, multiple readings for a chemical are detected. This could be explained by some problem in the functioning of the sensor.

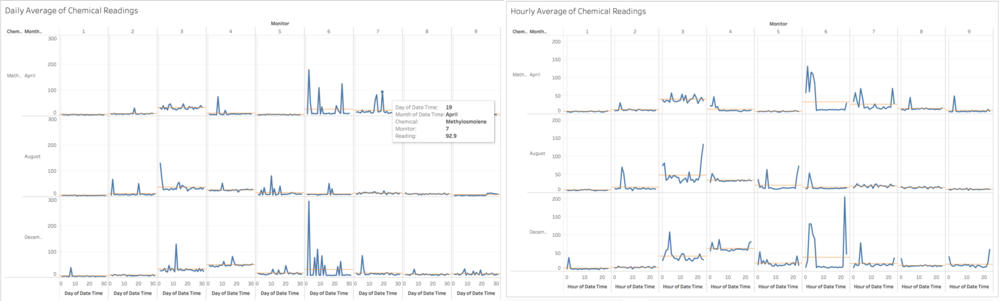

As seen in the figure on the left, Sensors 5 and 6 seem to record multiple readings for AGOC-3A quite often as compared to the other sensors. It is noticed the Methylosmolene has days with less recordings which could be due to the wind speed/direction.

As seen on the figure on the left, in August the sensors on a whole do not perform as well as they did in April. Sensors 4,5,6 have a lot of instances of multiple recordings of the same chemical at the same time on the same day. Sensors 7 and 8 are not shown in the plot because they seem to perform consistently across August.

As seen on the figure on the left, in December the sensors on a whole seem to perform better than August but still not as consistent as April. Sensors 4,5,6,9 have a lot of instances of multiple recordings of the same chemical at the same time on the same day. Sensors 7 and 8 are not shown in the plot because they seem to perform consistently across December.

Sensors 4,5,6 are the most inconsistent in terms of performance as compared to other sensors across the 3 months. Further analysis needs to be done to understand the reason for the inconsistency in the recordings by these sensors.

Analysis of Chemicals

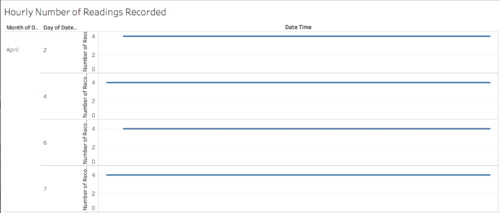

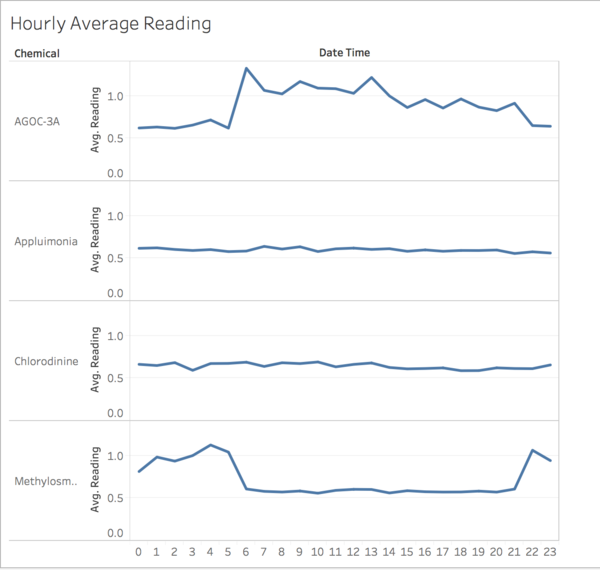

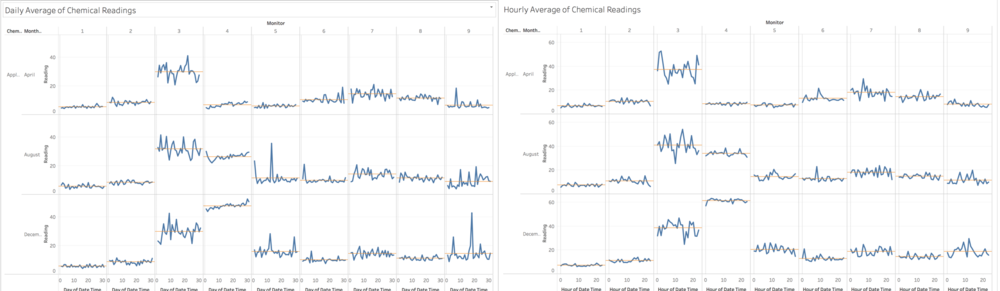

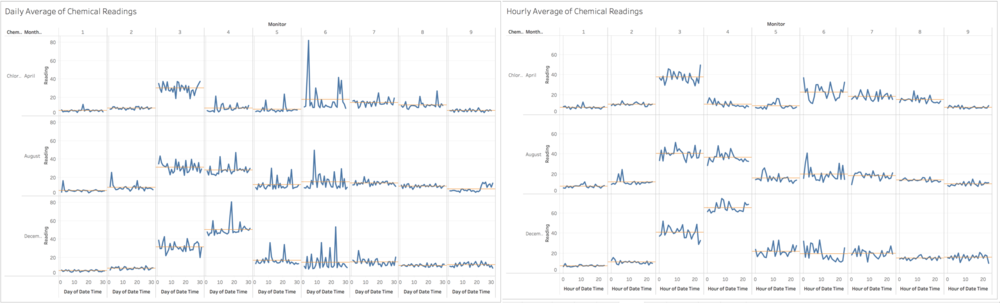

In the hourly overall graph we can spot two patterns as follows: AGOC-3A is emitted during 06:00 to 21:00 whereas Methylosmolene is emitted majorly during 21:00 to 6:00. Sufficient information is not available to understand if the two chemicals have a relationship or which function of the factory they are produced in which might increase their emission during certain times of the day.

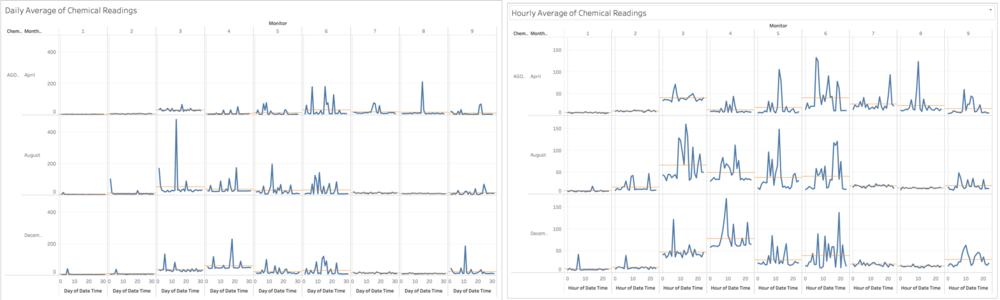

AGOC-3A

As seen in the daily average graph, this chemical seems to be majorly detected by sensors 3,4,5,6 while the highest peaks indicating the detection of chemical reading above average level are mostly sen in the month of August. This could be attributed to either the functioning of the factory and the wind. The anomaly seen in the month of August by sensor 3 could be due to the sensor's placement or its functioning. Further analysis could be done on this.

In the hourly graph for both overall and by chemical and the monitor, we can see that AGOC-3A is primarily emitted during 06:00 to 21:00. Sensor 6 shows a very inconsistent recording of readings on an hourly basis, this could be because of the factory that emits this chemical and is detected by 6 do not emit consistently or the detection by 6 is due to the wind speed and wind direction which can be inconsistent.

Methylosmolene

According to the daily graph, the chemical is comparatively consistent as compared to the latter months of August and December. For this chemical as well, sensor 6 seems to have very inconsistent readings and it is seen that for this sensor particularly, the maximum peaks are in the first half of the month. This again could be attributed to the factory that is influencing the readings of sensor 6 and the wind direction in combination.

According to the hourly graph, the peaks are mostly during the night time i.e from 21:00 to 6:00 which is also the pattern seen in the overall hourly graph. Further investigation can be done into this to understand whether the time of the day the chemical is emitted impacts its potency towards the environment and whether there are certain factories that increasing their emissions particularly at night.

Appluimonia

According to the daily graph, this chemical is released fairly consistently across all sensors and all months except Sensor 3. Sensor 3 exhibits the most readings and the highest variations as well. It can also be seen that the emissions have the highest variation on an hourly basis as detected by Sensor 3.

Chlorodinine

Similar to the previous chemical, Chlorodinine is also being released constantly throughout the 3 months of data. The release of this chemical typically spikes near the start and approaching the end of the month. Also, the level of concentration detected by Sensor 4 has increased dramatically from April to December in both daily averages as well as hourly averages. Sensor 6 seems to have a lot of high's and low's which are consistent across all months and all the other chemicals as well. Sensor 6 should be analysed to understand the reason behind the inconsistency int he readings.

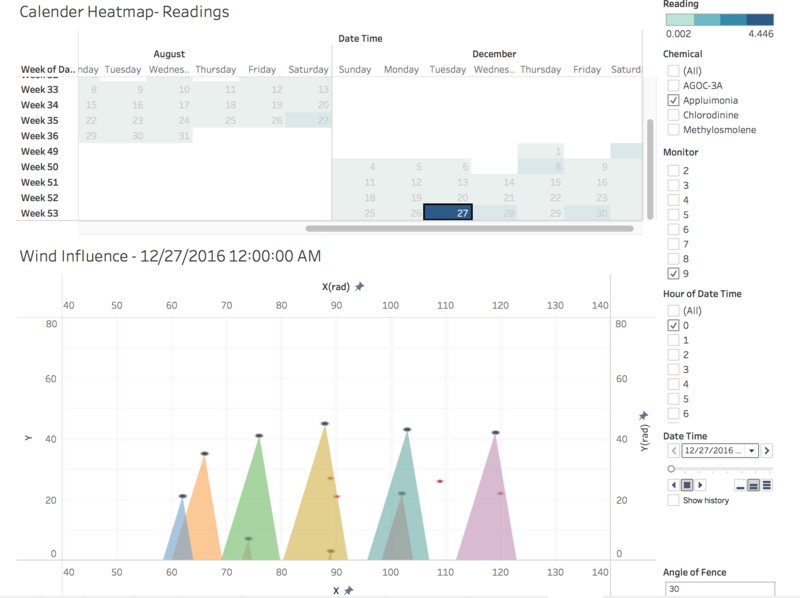

Analysis of Factories

Using the meteorological data, the influence range of a particular factory in 3 hour intervals can be determined. I assumed that the originating point of the wind is from the sensor and only the readings recorded every 3 hours were considered for this part of the analysis. On the basis of the pollution plume model, the angle of the fence is considered to be 30 degree by default and wind speed is converted to miles per hour and then scaled to the grid. In a lot of scenarios, clear distinction between roadrunners factory and Kasio factory cannot be made because they are quite close to each other and tend to be tagged together in the wind plume plot indicating that they both could be attributed to the rating. But it is difficult to determine the one cause of the high recording in this scenario.

On 17th April at 12PM, we can clearly see there is a spike in monitor 6. When we look at the wind plot, we can see that Radiance Factory is the one contributing to high recording for the chemical AGOC-3A.

On 27th December, we see a spike in recording for the chemical Appluimonia at 12:00 am at the sensor 9. According to the wind plot Indigo factory is the reason for the spike in recording.

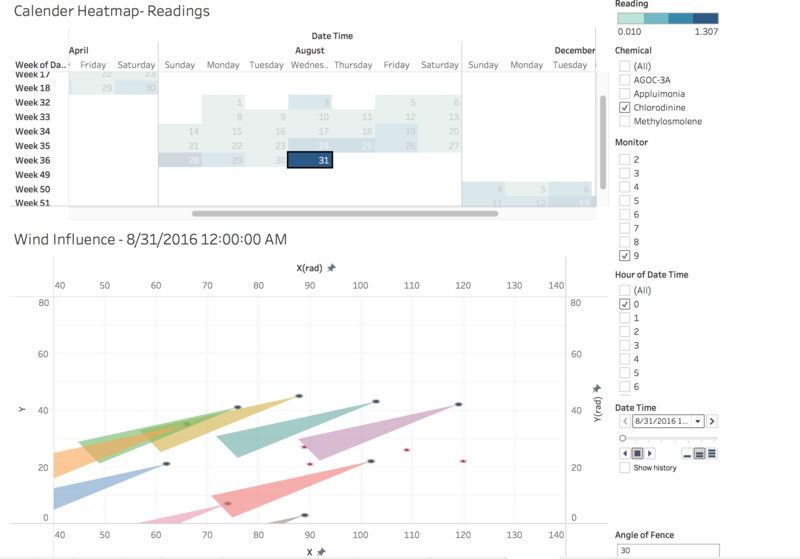

On 31st August 12:00 am, Sensor 9 recorded a very high reading for the chemical Chlorodinine. On anlalysing using the windplot we can see that Roadrunner factory is responsible for this reading but if we adjust our angle of fence, it is quite possible that Kasio also falls in the radar. Hence, roadrunner is not alone responsible although the default wind plot says otherwise.

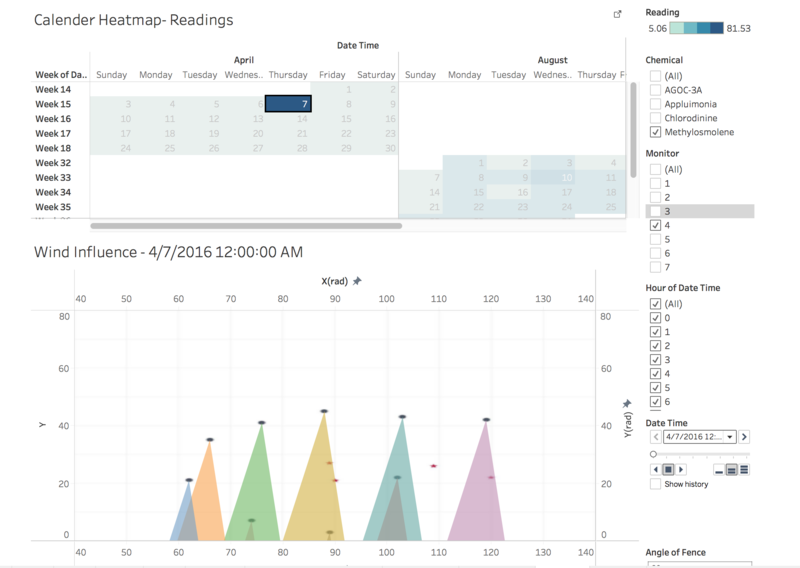

On 7th April 12:00 am, Sensor 4 records the highest reading for the chemical Methylosmolene and when we look at the windplot both Roadrunner and Kasio are contributing to the reading.

It is observed that in April wind blows torwards five main directions – north, northwest, west, south, southwest. This could be the reason why Sensors 2, 3, 6, 7 and 8 detected high hourly readings in April while other sensors were relatively dormant.Sensor 6 is located on the east and southeast side of Roadrunner and Kasios factories.This could be the reason why Sensor 6 readings are influenced by Radiance and Indigo and not Roadrunner and Kasio.

Comments

Hi Krutika,

I feel that In question 3, instead of using calendar map, cycle plot could be used to show the spikes on a particular day. Good analysis for question 1.

Hope it helps, Manish

Feedback 2 :

Hi Krutika,

Analysis is in-depth for the sensors and chemicals. As I have also done MC2, it was interesting to see how we both have used different visualization for investigating the malfunctioning sensors. For the chemicals analysis , especially appreciate the Sensor 6 finding that shows inconsistent recording. I missed out out that one!

For the analysis of the factories, perhaps you can form a list of factories and chemicals associated with it.

Hope this helps.

Thanks, Dipti